Lars Svensson and David Gillsjö met as doctoral students in WASP. They saw an opportunity in using technologies from autonomous systems and AI to create new tools for forestry that can help solve many of the industry’s challenges.

The company, Nordic Forestry Automation (NFA), was started in 2021 and has recently gotten off to a good start with a first investment round of SEK 10 million from, among others, the forestry companies Södra and Sveaskog. The first product, a sensor-based driver support for forest machines, will begin to be delivered in the autumn.

The founders got to know each other through the WASP Graduate School’s course program and study trips. Lars Svensson grew up on a forest farm, and already during the WASP era he started doing research and predicting future opportunities for autonomous systems to benefit the forestry industry.

“The basic idea for the company was to use the latest technology from autonomous systems and AI to create new tools for sustainable forestry,” says Lars Svensson.

As a first step, the founders built a test rig at home in the garage, with sensors, computing hardware and basic functionality for localization in forest environments, as well as detection, positioning, diameter measurement and species classification of trees. The prototype was shown to the forestry companies, and a dialogue was started to find out where in the forestry value chain there was real benefit with the technology in the short and long term. This led to the first application – a sensor-based driver support system for forest machines, as a first step towards an increased degree of automation in the industry.

“The biggest technical challenge is to achieve robust perception in the organic and unstructured forest environment, which also varies greatly from forest to forest. The broad general education about algorithm and software development, cloud and data management that we received from the WASP program has been very helpful in being able to attack the problem,” says Lars Svensson.

The sensor on a forest machine

Driving a forest machine in thinning or alternative forest management methods where you also only cut down a subset of the trees, means constant decision-making for the driver about which trees should be felled and which should be saved to best benefit the different values of the forest. The execution is crucial for the forest’s long-term development, but today it’s done completely manually and is based on the experience of the individual driver. The driver’s work entails a high cognitive load, which in turn leads to problems with production rate, quality of the result and high staff turnover.

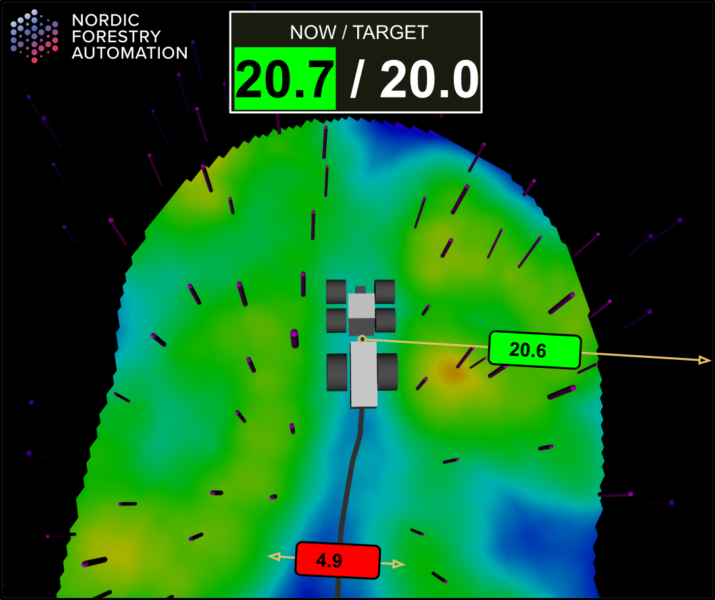

NFA’s first product is a sensor-based driver support system that can be retrofitted to any forestry machine and supports the driver in forest management decisions. The system measures, positions and classifies all trees around the machine automatically and in real time. The data on the trees is primarily used to support the driver with information about which trees should be removed and which should be saved to efficiently realize the specification for felling. In addition, the tree information is continuously saved and delivered to the forest owner. This enables quality assurance of the felling, increased transparency in the process, and new opportunities for the forest owner to implement alternative management methods.

The user interface of the product.

“We see sensor-based driver support as an enabler for more varied forestry. The technology creates the conditions for all drivers to effectively implement any management method, so that every forest owner can conduct exactly the forestry they want. For example, you can choose methods that favor biodiversity or increased carbon storage in the forest,” says Lars Svensson.

Since the investment round was completed last spring, the team and the pace of development have increased rapidly, and already in the autumn the first pre-series systems are delivered to selected early-adopter customers. The company continues to grow, and in the future the aim is to develop the technology towards autonomous systems for forestry.

“The basic ability to build a digital representation of the forest environment in real time has a variety of application areas. We see ahead of us a sequence of products with a progressively increasing degree of automation in forestry. In the same way as the development seen in, for example, the automotive industry,” says Lars Svensson.

In conclusion, he also hints that they want to grow the team and that the people in WASP is a key group with skills that they need more of.

More info about Nordic Forestry Automation

More information about the company and contact information: https://www.nordicforestryautomation.com/

Published: November 6th, 2023

[addtoany]